Slitting is the process of cutting large rolls of raw materials into smaller rolls using a blade. This article explores in detail the slitting process, types of slitting machines, its applications in industries such as steel, plastic, paper and the benefits this process brings. Slitting helps increase production efficiency, save costs and ensure product quality. Plays an important role in optimizing industrial production processes.

Slitting concept

Slitting, also known as vertical cutting, is the process of cutting large rolls of raw materials into smaller rolls using a knife or blade. This process is often applied to materials such as metal, paper, plastic and fabric.

Slitting Process

The slitting process includes the following basic steps:

- Prepare raw materials: Large rolls of raw materials are placed into the slitting machine.

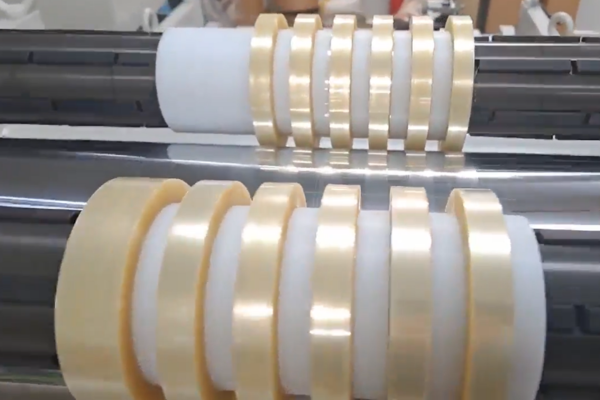

- Blade setting: The blade is set to the desired distance to produce smaller rolls of the required size.

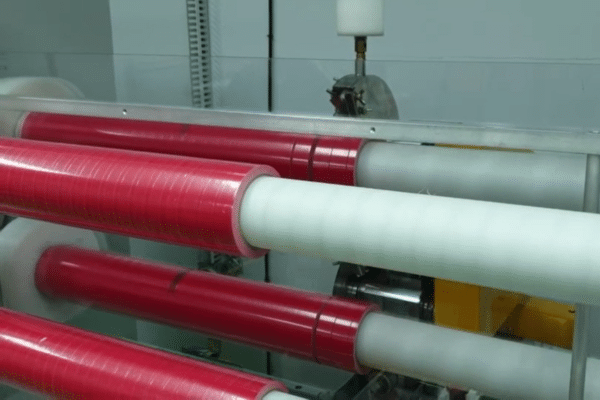

- Cutting process: Material is passed through cutting blades, creating smaller rolls.

- Collecting rolls: After cutting, small rolls are collected and packaged to continue the production or transportation process.

Types of Slitting machines

- Single shaft slitting machine: Suitable for thin and light materials.

- Dual shaft slitting machine: Used for thicker and heavier materials.

- Automatic slitting machine: Integrating automation technology helps increase productivity and reduce errors.

Application of Slitting

Slitting has widespread applications in many industries, including:

- Steel industry: Slitting is used to cut large steel coils into smaller coils for the production of various steel products.

- Plastic industry: Slitting process helps create smaller plastic rolls. Ease of handling and manufacturing of plastic products.

- Paper industry: Slitting helps cut large rolls of paper into small rolls, serving printing and paper packaging production.

Benefits of Slitting

- Increase production efficiency: Helps optimize production processes by creating smaller rolls of material that are easier to handle.

- Cost savings: Reduced material waste and shipping costs due to using smaller rolls.

- Ensuring product quality: Helps control the size and quality of raw material rolls, ensuring output products meet standards.

Slitting is an important process in industrial production, helping to increase efficiency and product quality. With the development of technology, slitting machines are increasingly improved, meeting the increasing needs of industries.

DONGWOOST VINA COMPANY LIMITED

- Hotline: 0222.222.0261 – 0971.499.958 – 0968.637.530

- Address: Dai Dong – Hoan Son Industrial Park, Hoan Son Commune, Tien Du District, Bac Ninh Province

- Gmail: dongwoostvina0602@gmail.com

- Website: https://dongwoost.com/