Roll Cutter is an important equipment in many industries, helping to optimize production processes and improve product quality. Choosing and using the right type of roll cutting machine will bring many benefits to businesses. From saving costs, increasing productivity to improving product quality.

What is Roll Cutter?

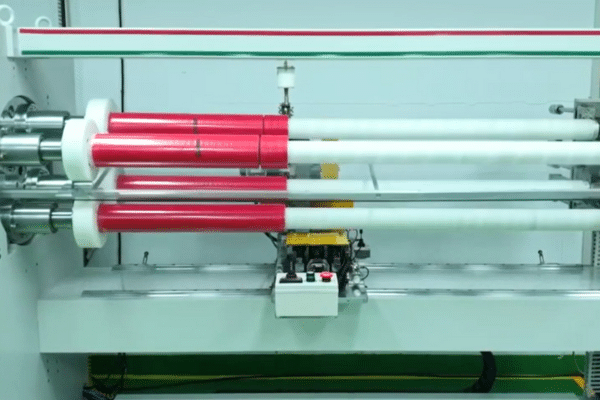

Roll Cutter is a specialized device used to cut rolls of raw materials into smaller sizes. These rolls of material can be paper, fabric, plastic film, rubber or other types of materials used in the manufacturing industry.

Principle of operation

Roll Cutter operates on the principle of vertical or horizontal cutting. Depends on the design and intended use of the machine. Some popular types of roll cutters include:

- Slitting Machine: Cuts the roll of raw materials lengthwise, dividing the roll into smaller strips.

- Crosscutting Machine: Cuts rolls of raw materials horizontally, forming small sheets or pieces.

- Edge Trimming Machine: Trims off the excess edges of the material roll to create a smooth and uniform surface.

Application of Roll Cutter

Roll Cutter is widely used in many industries, including:

- Paper and packaging manufacturing industry: Cut paper rolls into smaller sizes to produce packaging, books, newspapers and magazines.

- Textile industry: Cut fabric into small pieces to produce clothes and accessories.

- Plastic film and protective film manufacturing industry: Cut plastic film into smaller sheets for use in packaging and product protection.

- Rubber manufacturing industry: Cutting rubber into small pieces to produce tires and technical rubber products.

Benefits of using Roll Cutter

- Save time and manpower: Automatic roll cutting process reduces effort and time compared to manual cutting.

- High precision: The roll cutting machine ensures high precision in each cut, helping the final product achieve good quality.

- Increase productivity: With the ability to cut quickly and continuously helps increase production productivity.

Factors to consider when choosing Roll Cutter

- Type of material to be cut: Depending on the type of material (paper, fabric, plastic film, rubber), you will need to choose the appropriate cutting machine.

- Thickness and size of the material roll: Determine the thickness and size of the material roll to choose a cutting machine with good processing capabilities.

- Cutting speed and accuracy: Choose a cutting machine with speed and accuracy appropriate to production requirements.

- Cost and maintenance: Consider the initial investment cost and periodic maintenance costs of the mower.

If you are looking to buy quality, cheap Roll Cutter. Please contact us at the address below.

DONGWOOST VINA COMPANY LIMITED

- Hotline: 0222.222.0261 – 0971.499.958 – 0968.637.530

- Address: Dai Dong – Hoan Son Industrial Park, Hoan Son Commune, Tien Du District, Bac Ninh Province

- Gmail: dongwoostvina0602@gmail.com

- Website: https://dongwoost.com/